Understanding Bow Stranding Machines: A Key Component in Wire Manufacturing

Release time:

2025-01-22

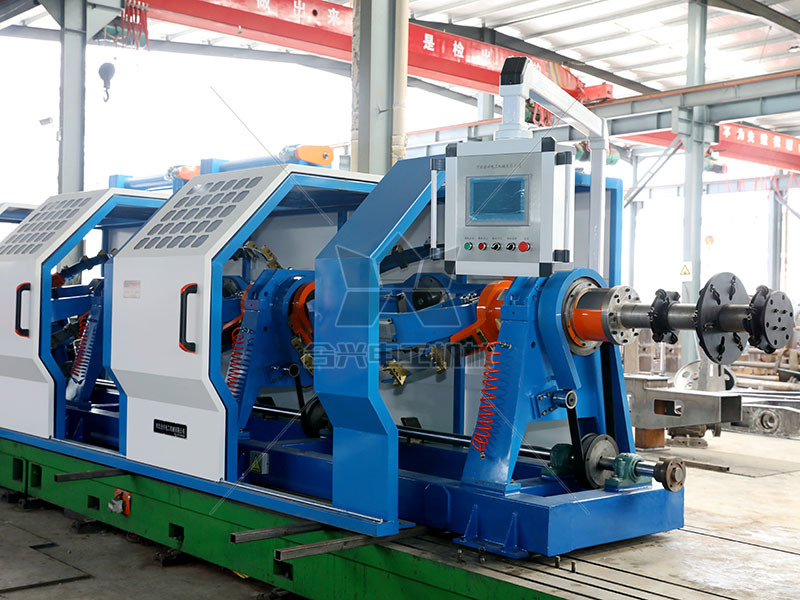

In the realm of electrical and electronic product manufacturing, Bow Stranding Machines play a pivotal role in the creation of high-quality wire products. These machines are specifically designed for the stranding of conductors, allowing multiple wires to be twisted together to form a single, cohesive strand. This process is crucial for enhancing the electrical conductivity and mechanical properti

A Bow Stranding Machine operates by employing a unique arrangement of rotating arms and bow-shaped guides. The design of these machines facilitates the even distribution of wires as they are twisted together, ensuring consistency in diameter and tension throughout the strand. The precise engineering behind this machinery not only contributes to the efficiency of production but also minimizes the risk of wire damage during the stranding process.

One of the primary advantages of Bow Stranding Machines is their ability to handle multiple wire sizes and materials. Whether working with copper, aluminum, or other conductive materials, these machines can be adjusted to accommodate different wire thicknesses. This versatility makes them an ideal choice for manufacturers looking to produce a wide range of wire products, from automotive cables to high-voltage transmission lines.

Additionally, Bow Stranding Machines are equipped with advanced control systems that allow operators to monitor and adjust parameters in real-time. This feature enhances the overall quality control of the production process, ensuring that each strand meets the required specifications. By leveraging technology, manufacturers can achieve higher production rates while maintaining stringent quality standards.

The efficiency of a Bow Stranding Machine not only impacts production timelines but also contributes to cost savings. By reducing material waste and improving operational speed, these machines enable manufacturers to optimize their resources effectively. Moreover, the durable construction of Bow Stranding Machines ensures a long service life, further enhancing their value in the production line.

In conclusion, Bow Stranding Machines are an integral part of the electrical manufacturing industry. They facilitate the reliable and efficient stranding of wires, enhancing both the performance and durability of the final product. With their versatile capabilities and advanced technology, these machines are essential for any manufacturer aiming to produce high-quality electrical wiring. As the demand for efficient and reliable electrical components continues to grow, understanding the significance of Bow Stranding Machines becomes increasingly important for professionals in the field.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province